Bryce

New member

No, this is not about our new cyborg-bird (cybird?) masters. I've been working on some specialized peripheral devices for parrots. My goal here is to build a 'video game' that my gray, Ruby, can play while I'm away from home. She figures out conventional foraging toys really quickly, and I think it's time to go digital.

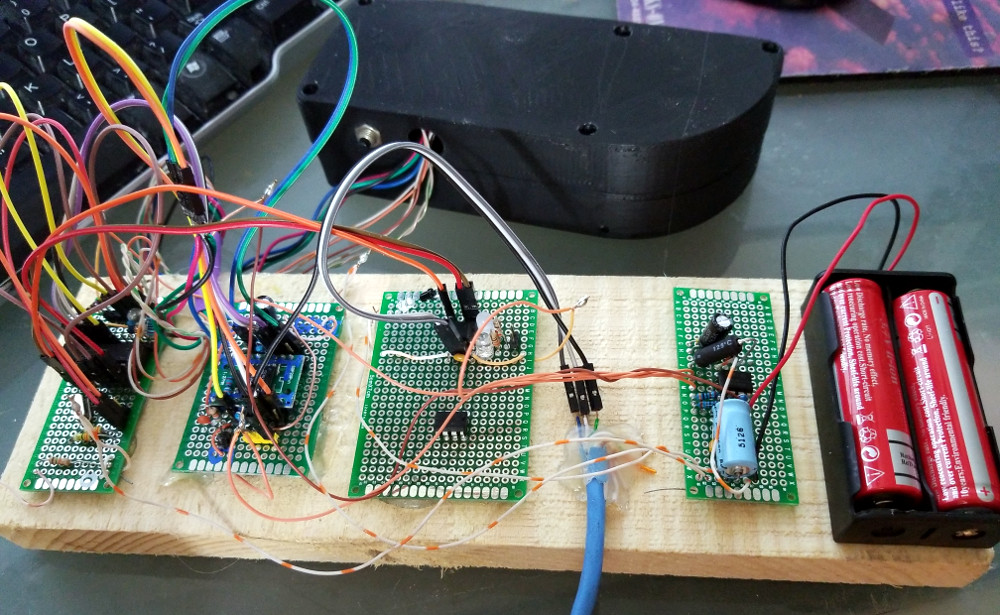

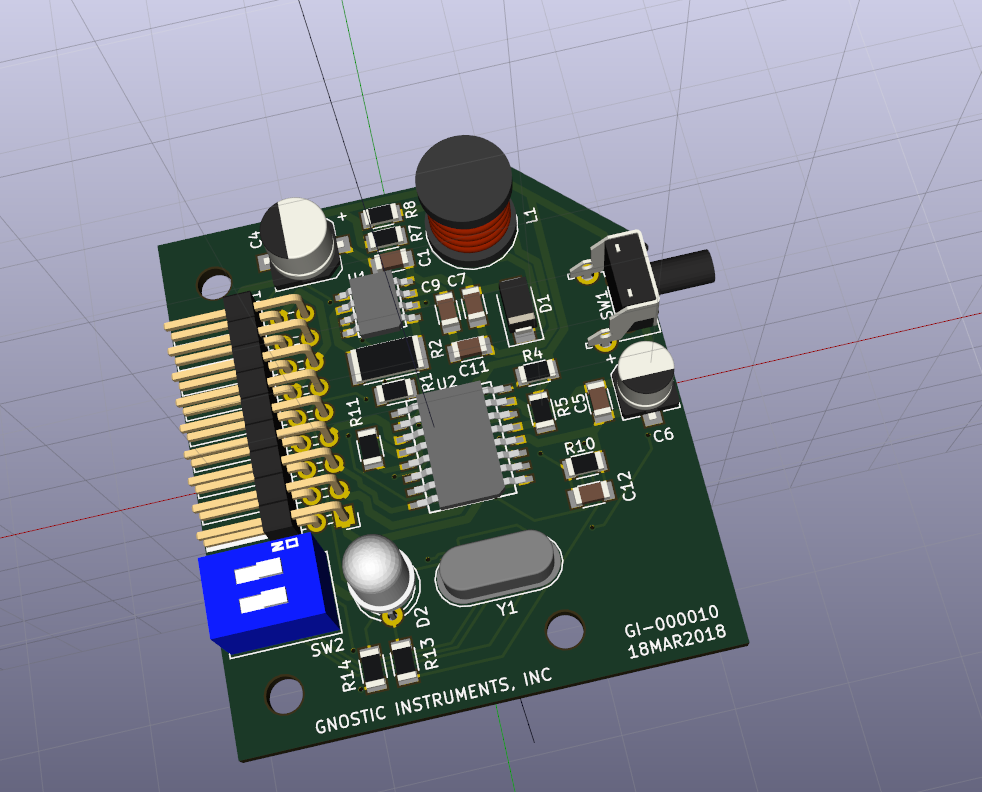

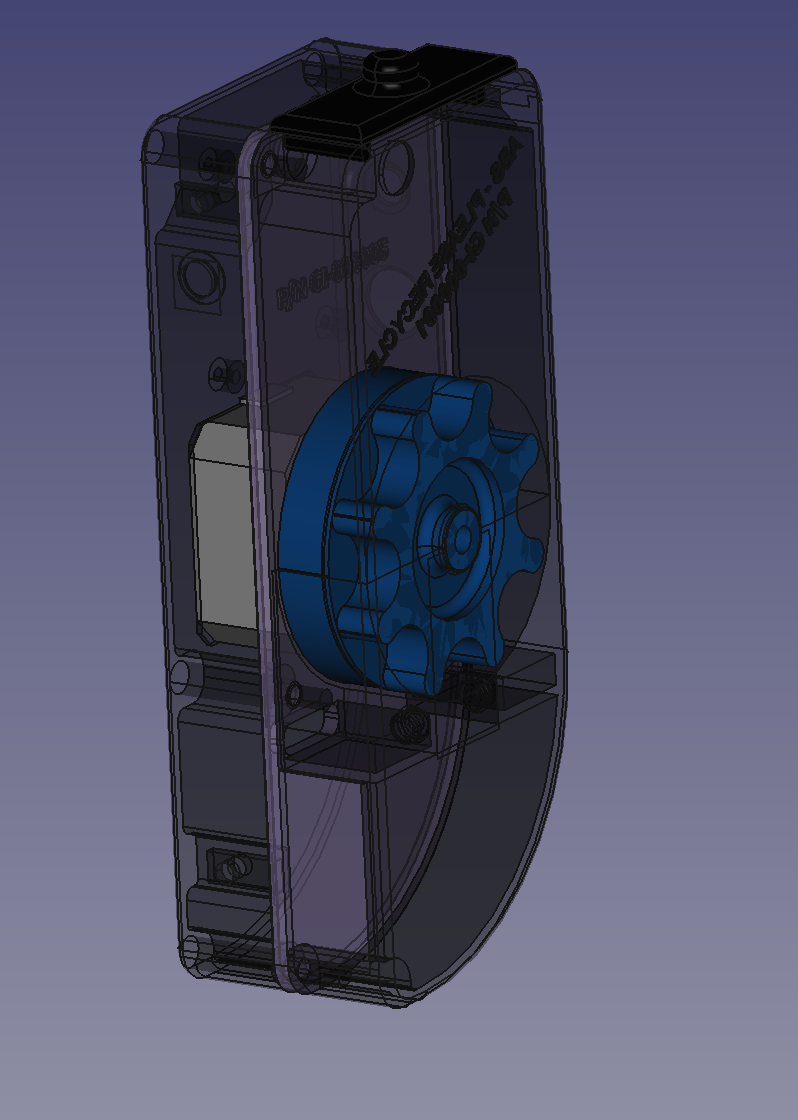

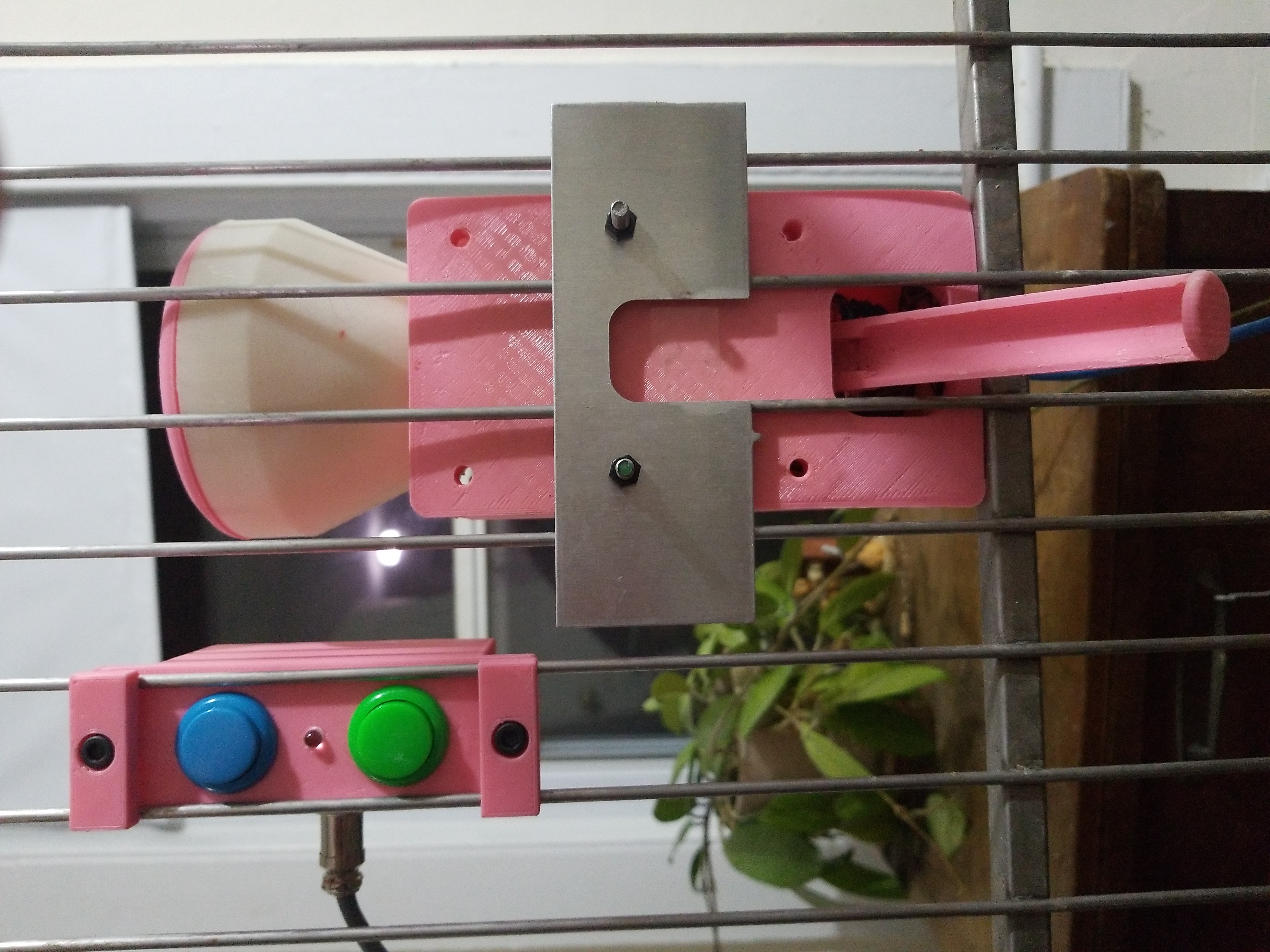

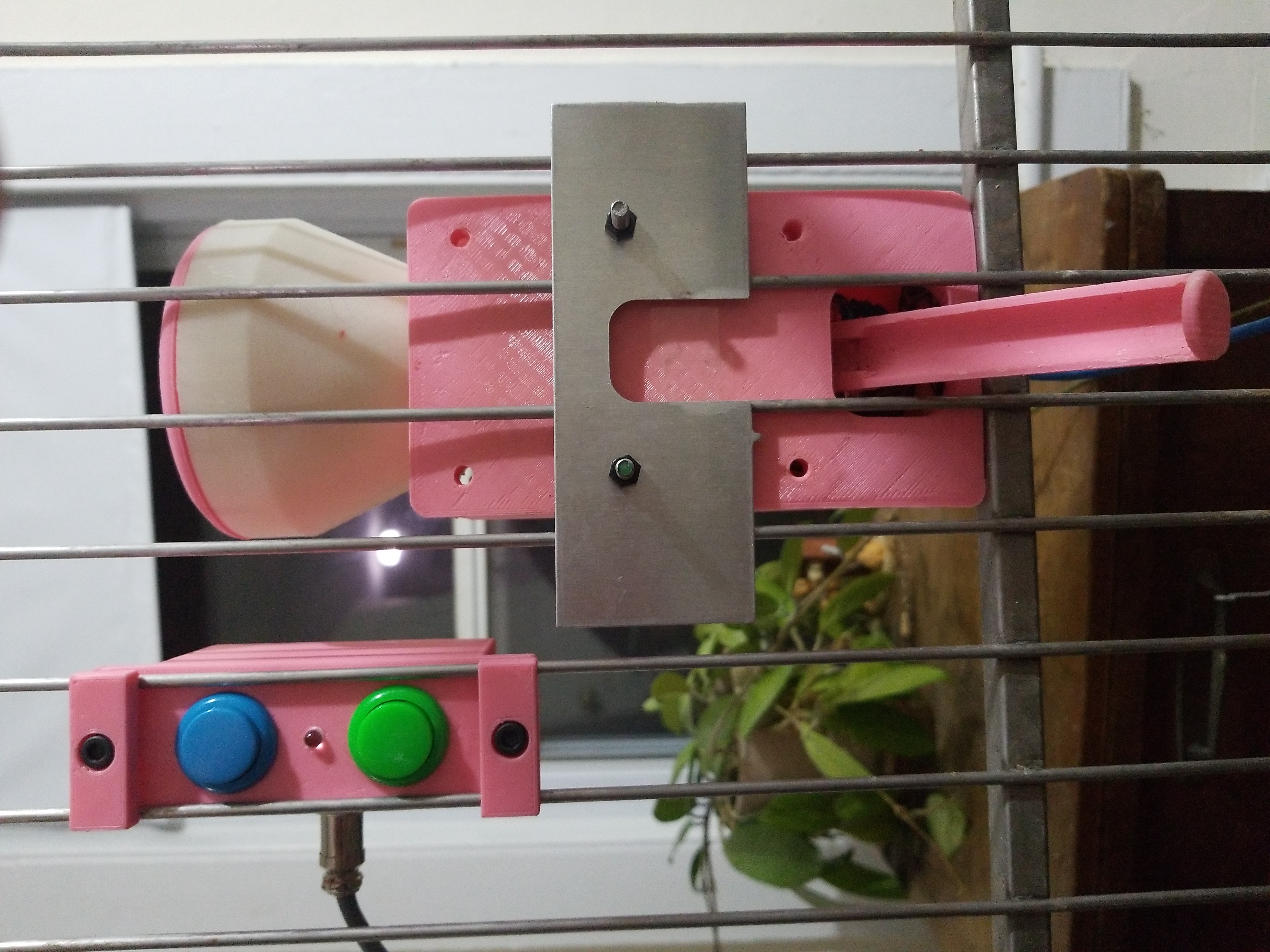

So far, I've made a treat dispenser and a controller box with buttons.

I'm going to connect these peripherals to a single-board computer, probably a BeagleBone (similar to a Raspberry Pi) and try to implement a simple pong-like game. Ruby will press the buttons with her beak to move the paddle, and get rewards from the dispenser for performance. Of course, I expect to have to train her to do this in gradual steps (beginning with just getting rewards for pressing the buttons.)

When I get these things more refined, I'll post more details about their construction. I've already got quite a few changes to make to the dispenser based on Ruby's feedback. She was frightened of it the first time it dispensed a treat, but after seeing goodies come out of it when it made that noise about twice, she started to respond to the noise by rushing over to the chute in anticipation instead of retreating.

Many of the components of both the button box and the dispenser are 3D printed. The buttons on the button box are arcade machine buttons, which I'm hoping will stand a good chance of surviving The Beak.

So far, I've made a treat dispenser and a controller box with buttons.

I'm going to connect these peripherals to a single-board computer, probably a BeagleBone (similar to a Raspberry Pi) and try to implement a simple pong-like game. Ruby will press the buttons with her beak to move the paddle, and get rewards from the dispenser for performance. Of course, I expect to have to train her to do this in gradual steps (beginning with just getting rewards for pressing the buttons.)

When I get these things more refined, I'll post more details about their construction. I've already got quite a few changes to make to the dispenser based on Ruby's feedback. She was frightened of it the first time it dispensed a treat, but after seeing goodies come out of it when it made that noise about twice, she started to respond to the noise by rushing over to the chute in anticipation instead of retreating.

Many of the components of both the button box and the dispenser are 3D printed. The buttons on the button box are arcade machine buttons, which I'm hoping will stand a good chance of surviving The Beak.